Counterfeit Electronic Components an Overview

January 4, 2022

Almost all finished goods are produced by, contain, or manufactured with systems using electronic parts that manage operations. The semiconductor market alone continues to expand past the $425.96 billion mark measured in 2020. With high demand and constrained supply due to current economic factors, genuine product prices have increased along with the lead times to delivery. These factors have also re-energized another unfortunate side business in fraudulent and counterfeit electronic parts. By definition, other than genuine electronic parts fall into three categories:

- Suspect parts are those where initial inspection of the shipment shows evidence that the product supplied may not be as represented by the seller.

- Fraudulent parts are those misrepresented to the buyer as new compatible parts meeting the customer’s needs, without regard to actual condition or performance specifications.

- Counterfeit parts are fraudulent but misrepresented as new, certified, and authorized products marked as genuine with the intent to mislead or defraud the buyer. Counterfeit parts can be difficult to identify with a casual inspection.

All categories bring a potential for risk and peril. Engineered systems that perform critical tasks can endanger life and property when fraudulent part failures halt operations in unpredictable ways.

The Origin of Fraudulent or Counterfeit Parts

Stolen parts from the original component manufacturer (OCM) or authorized manufacturers can appear in supply chains at lower than expected costs. While identical to OCM products, those of uncertain or different origins from genuine parts supplies risk loss of warranty from the OCM or can be subject to sabotage through destructive malware or other tampering affecting the quality of the lot.

Sold-off new parts, excess inventory, or obsolete products can be repackaged and re-labeled to resell out of specification, expired, or un-warranted parts.

Electronic waste provides mountains of used parts that may be recovered from discarded circuit boards and cleaned up, remarked, and sold as new. The purchase price is usually too good to be true and the part will likely not function as represented.

Counterfeit production from stolen intellectual property (IP) may function for a while, but the quality is usually sub-par, and materials often do not meet OCM specifications. Counterfeit product is very difficult to discover because prices may be close to the OCM price but slightly lower. Some clues are an abnormal supply chain path and inaccurate markings compared to genuine products.

Avoidance of Fraudulent and Counterfeit Parts

Know your supplier

Develop your supplier list from established distribution channels with direct relationships to original equipment manufacturers (OEM) and OCM companies whose parts you use. Standing relationships with OEM offer low-risk sources of replacement parts directly from the OCM or an authorized aftermarket manufacturer. Purchase safety and key characteristic critical components only from the OCM or OEM. Consult with a certified repair center for additional resources to help identify accredited vendors and suppliers.

Identify Contactor approved suppliers (CAS) known as trustworthy by a contractor or subcontractor. When evaluating new suppliers, consider those that perform inspection, test, and authentication methods supporting SAE AS5553 and AS6081 practices.

Support countermeasures

Register and make use of the Government-Industry Data Exchange Program (GIDEP) and Electronic Resellers Association International (ERAI) databases to report and check on suspected parts reported by others.

Tips for Spotting Fraudulent and Counterfeit Parts

- Trust your instincts. If you suspect a problem contact the OCM for verification of serial numbers. Serial numbers are not the same as the lot or batch numbers but are unique and not duplicated.

- Perform inspection of all incoming shipments and verify documentation against the products in the order. The time spent for verification can be less costly than repairs or rework on defective assemblies with fraudulent parts.

- Get a quote from the OCM or OEM for comparison if not purchasing from OCM or OEM.

- Avoid unfavorable production choices that can inadvertently open the door to fraudulent components. Consider that accelerated build schedules, expedited part shipments, and just-in-time (JIT) procurement practices invoked at any time during the project assert pressure on all internal and external participants to make poor choices.

- Never admit parts and materials without incoming inspection and verification. Use your established quality management (QM) procedures and documentation to minimize problems with the project.

- Do not select new vendors or distributors without proper evaluation.

- Avoid purchases from unverified Web sources.

- Select offshore and outsourcing partners with the same level of evaluation as your best, most trusted vendors.

- If possible, compare with an original component for significant differences such as weight and construction of the device. Make sure it wasn’t machined and cleaned to look new.

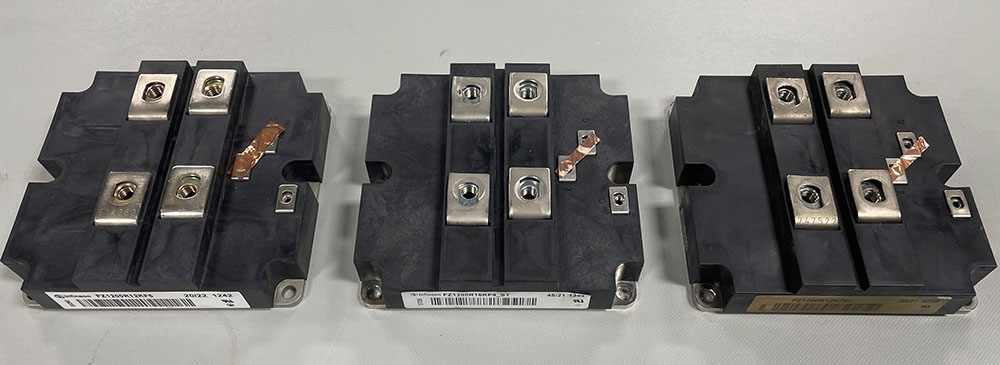

- Use caution when sourcing parts (IGBTs and OEM electronic assemblies) for obsolete equipment. Counterfeits are becoming quite sophisticated, but performance is severely lacking, or worse, they can be dangerous to operate.

Diligence Over Shortcuts

Diligent review and common sense are valuable weapons in the fight against fraudulent parts. Taking shortcuts can result in unimaginable expenses and liabilities. Developing and observing best practices protect both the company and the company’s customers.